AMANECO PROJECT

“Assessment of additive manufacturing limits for eco-design optimization in heat exchangers”

Eco-design: a transverse activity for eco-compliant products in the aeronautical industry

The aeronautical industry needs to anticipate and address the requirements for eco-compliant products, developing effective technologies and assessment tools to be able to reach the same level of eco-compliance that exists in other sectors.

Improvement of ecological impact of aeronautical products through new development in materials, surface treatments, production methods (like additive manufacturing) and recycling will imply a reduction of primary energy demand in production, waste and emissions, and increase recyclability.

Additive manufacturing is key for improved design and production process of aviation parts.

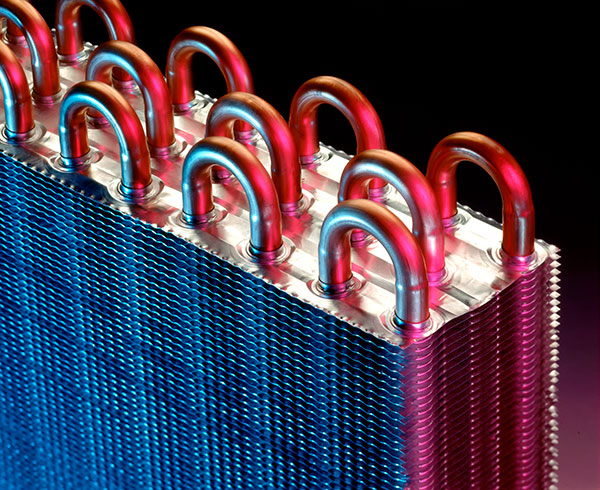

Additive manufacturing, and particularly Laser Powder Bed Fusion (LPBF), could dramatically improve global eco-efficiency of heat exchangers through access to radically new designs and open horizons in terms of shape, weight and efficiency. Nevertheless, some questions need to be solved regarding capability to manufacture thin walls, small holes/gaps, low overhang angle, resulting surface roughness and mechanical strength.

Main Innovation

Enhance knowledge of metal Additive Manufacturing and, specifically, the capability of LPBF process to manufacture thin wall thickness with adequate surface finish for heat exchangers using AlSi7Mg0.6 and INCO 718 materials.

The project

Eco-design of heat exchangers

It covers the full cycle, from initial approach to increase efficiency and reduce weight to end-of-life disposal. Aerothermal and mechanical performance of thin walls will be investigated to predict them in the design of heat exchangers and consequently, be able to optimize their design process in an Eco-friendly way after knowing the limits of the metal Additive Manufacturing technology.

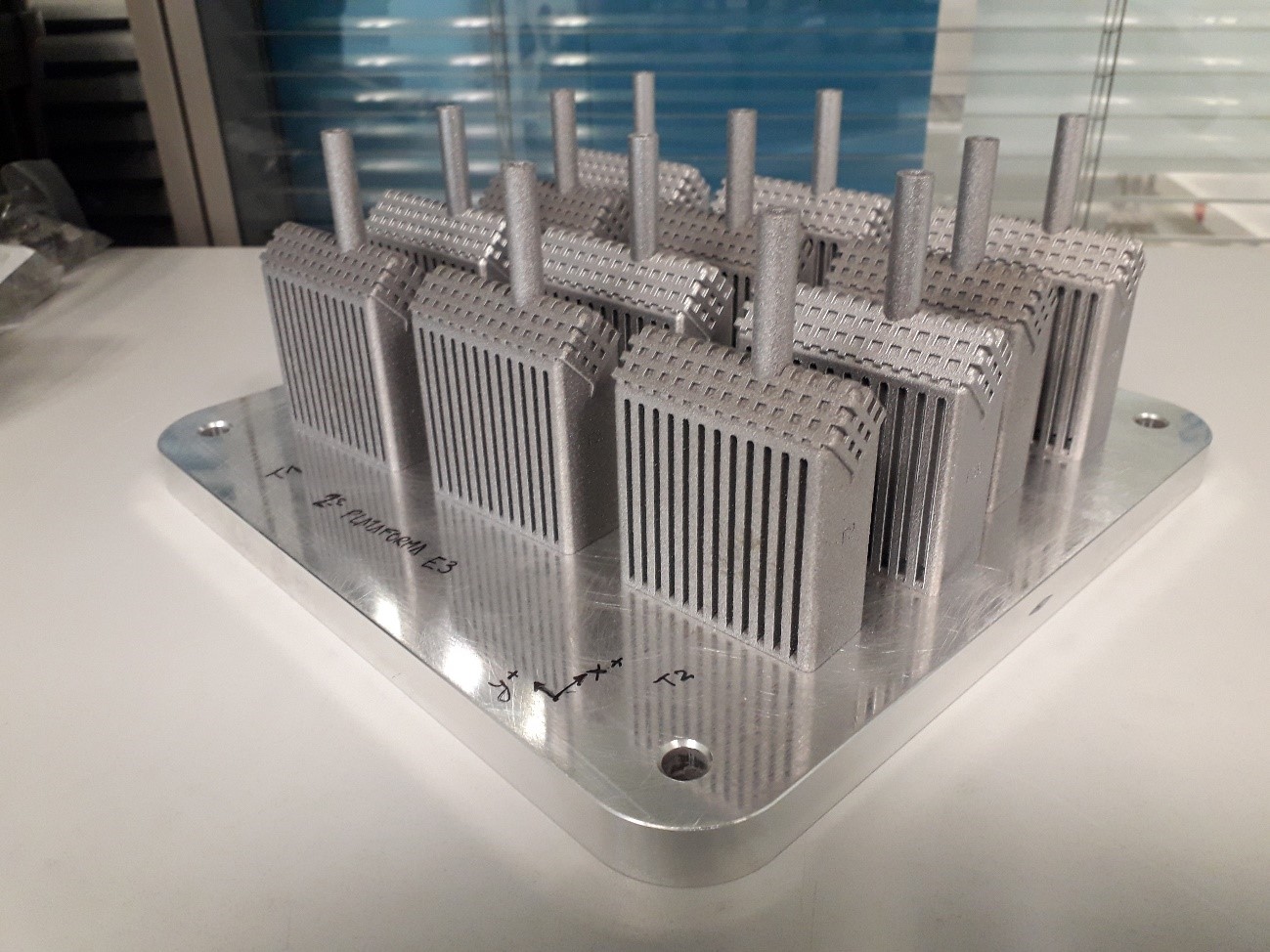

Prototyping

A new heat exchanger design will be developed and manufactured by metal Additive Manufacturing using LPBF process. CAD model of a sample representative of the design, based on the initial state of the art of additive manufacturing limitations, would be the base for an optimized design with redesign, optimized wall thickness, heat transfer elements and so on. The optimized design will comprise a plate and/or fins sample geometries to enhance the heat transfer and the overall efficiency of the innovative heat exchangers.

Methodology

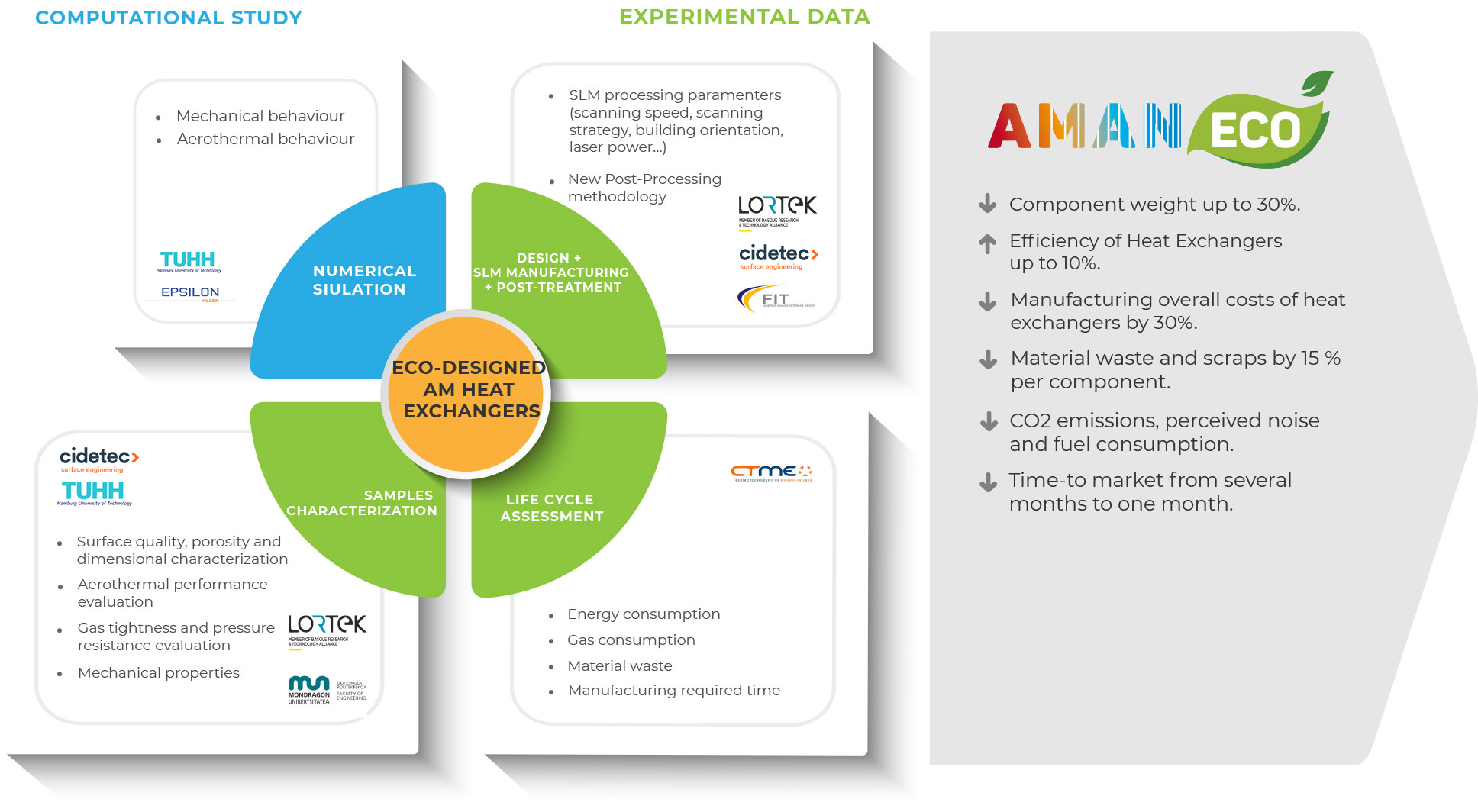

Testing samples will be designed and manufactured to characterize in terms of surface properties, pressure resistance and gas tightness evaluation, equivalent stiffness and aerothermal properties. Besides, numerical studies based on FEM and CFD simulations will be done. Then, a representative design of heat exchanger based on the initial state-of-the-art of Additive Manufacturing limitations will be optimized with the gained knowledge. These designs, before and after optimization, will be processed and characterized. Finally, a Life Cycle Inventory (LCI) database will be created and a Life Cycle Impact Assessment will be performed to evaluate the ECO potential of the innovative heat exchanger.

Industrial objectives

- To reduce time-to market from several months to one month due to the manufacturing of the aerospace engine components as soon as the 3D design has been created.

- To increase efficiency of Heat Exchangers up to 10% by means of innovative designs.

- To reduce the overall cost of the manufacturing of heat exchangers by 30% due to reduction of time-to market, on-demand manufacturing, lightweight design and increased productivity of the new components.

- To obtain enhanced structural integration, reduced costs and weight in the aircraft industry.

Environmental objectives

- To reduce material waste and scraps by 15 % per component due to dimensional inaccuracies and excessive wall thickness.

- To reduce CO2 emissions, perceived noise and fuel consumption due to the weight reduction of engine parts and adequate aero-thermal performance.

- To contribute to the development of next generation of High Performance and Energy Efficient Airframe structures such as the Ultra-High Propulsive Efficiency engine with less environmental impact.

Impact

A novel process to develop more efficient heat exchangers

Access to radically new designs considering Eco-design aspects, opening new horizons in terms of optimization of shape, weight and efficiency.

Optimisation of the conception phase of heat exchangers reducing their development time/cost/energy by assessing the limits of LPBF technology (wall thickness, holes/gaps, overhang angle, surface finish, etc.) and including them in the design tool.

Optimisation of the material used for the same efficiency, by optimising the wall thickness in heat exchangers or through new shapes with improved heat transfer capacity. Lightening up to 40% is expected (volume reduction in 3 times).

Environmental benefits

A reduction in material waste and scraps by 15 % per component is expected.

A weight reduction of the component up to 40% is foreseen. Thus, besides having a positive impact in fuel need, expected CO2 reductions are:

- 1.38 kg CO2 emissions reduction per each kg of motor reduced.

- 9.45 kg CO2 equivalent emissions per kg and 10.000 km flight.

Main Results

-

Design of testing samples fully developed.

- Surface properties characterization of samples made with AlSi7Mg0.6 and INCO718 materials.

- Gas tightness evaluation of samples made with AlSi7Mg0.6 and INCO718 materials.

- Pressure resistance evaluation of samples of AlSi7Mg0.6 material.

- Finite Element simulation of mechanical behaviour of samples of AlSi7Mg0.6 and INCO 718 materials.

E3 samples manufactured by SLM for gas tightness and pressure proof evaluation

E4 samples manufactured by SLM for equivalent stiffness characterization

Innovation activities

The work plan is divided into 7 WPs - 2cross-cutting WPs (dedicated to Project Management and to Dissemination and Exploitation), and 5 technical WPs – with a duration of 36 months (from 1st October 2019 to 30th September 2022).

WP1 is dedicated to the specifications related to the test sample geometry definition and characterization and the definition of critical environmental aspects to be considered in the Life Cycle Inventory (LCI). The manufacturing and characterization planning details of this heat exchanger design will be developed.

WP2 will address the compliance of the both powders (INCO 718 and AlSi7Mg0.6) quality according to Safran specifications. After performing the powders quality assurance, all testing sample manufacturing will be carried out.

WP3 will be focused on the characterization of all samples: surface properties, aerothermal behaviour, pressure resistance and gas tightness and mechanical performance by equivalent stiffness characterization. In addition, the dimensional accuracy will be evaluated.

WP4 will address the numerical study in terms of FEM simulations for pressure proof and equivalent stiffnes and CFD simulations for aerothermal performance. The results obtained by these numerical studies will be compared with experimental results obtained in WP3.

WP5 is dedicated to the assessment of the final design optimisation of a heat exchanger. The new design of the heat exchanger will be manufactured and afterwards a complete characterization as the one performed in WP3 will be carried out. LCI data will be measured and collected and the Eco potential of these heat exchangers will be assessed.

Dissemination activities

AMANECO kick-off meeting

23-24 October 2019

The project was launched during the kick-off meeting that was held on the 23th and 24th of October 2019 in the headquarters of LORTEK in Ordizia (Spain). All partners and the topic manager SAFRAN participated in the meeting.

The participants shared a common vision of the project needs, objectives, planning and tasks for the successful future outcomes. The working plan was set up and validated and the participants had the opportunity to visit the facilities of Lortek.

PRESS RELEASE

The project was explained three times in the “Estrategia Empresarial” magazine, the newspaper of the Spanish industry:

- Press release where the overall objective of AMANECO project is described (Estrategia Empresarial, 16-29th February 2020, pag 7)

- Press release where the main objective of the project was described as well as the advantages of developing new design of heat exchangers with lower wall thickness than in the current state of the art. The impact on the heat exchangers efficiency and the environmental benefits were also highlighted. (Estrategia Empresarial, 16-28th February 2021, pag 9)

- Press release focused on the surface treatment developed for reducing the roughness of heat exchangers developed by additive manufacturing. (Estrategia Empresarial, 16-30th April 2021, pag 9)

Consortium

AMANECO project will be carried out by 7 partners from 3 different countries (Spain, Germany and France), with complementary skills and experience, covering the whole project value chain. The partners are referent entities in their fields at European level.

LORTEK is the project coordinator. Due to their expertise in additive manufacturing, LORTEK and FIT will be focused of the manufacturing of samples and prototypes by additive manufacturing, while TUHH will be in charge of heat exchanger design and numerical simulation.

CIDETEC and Mondragon Unibertsitatea will be in charge of sample characterization, while EPSILON will perform aerothermal numerical simulation and CTME life cycle assessment and eco-design.

SAFRAN is the Topic Manager and will steer the AMANECO project included in the Engines (ENG) and Eco-Design Programmes of the Clean Sky2 Joint Undertaking.